CHARACTERISTICS

EDGE BANDER

Woodman Profesional has a wide range of professional Edgebanders. The technological and design solutions offered by our models allow us to address the entire professional sector, from the small carpentry workshop, furniture manufacturers, construction, and reform.

Machines equipped with the best features, the latest technology that provides us with high performance with intuitive and user-friendly handling.

The customization of the models allows us the ideal composition of units for different processes and finishes depending on the material to be worked.

EDGE BANDER PRO3RCT PLUS

With a compact and improved touchscreen, PRO3RCT PLUS achieves a higher quality finish with its corner rounding unit.

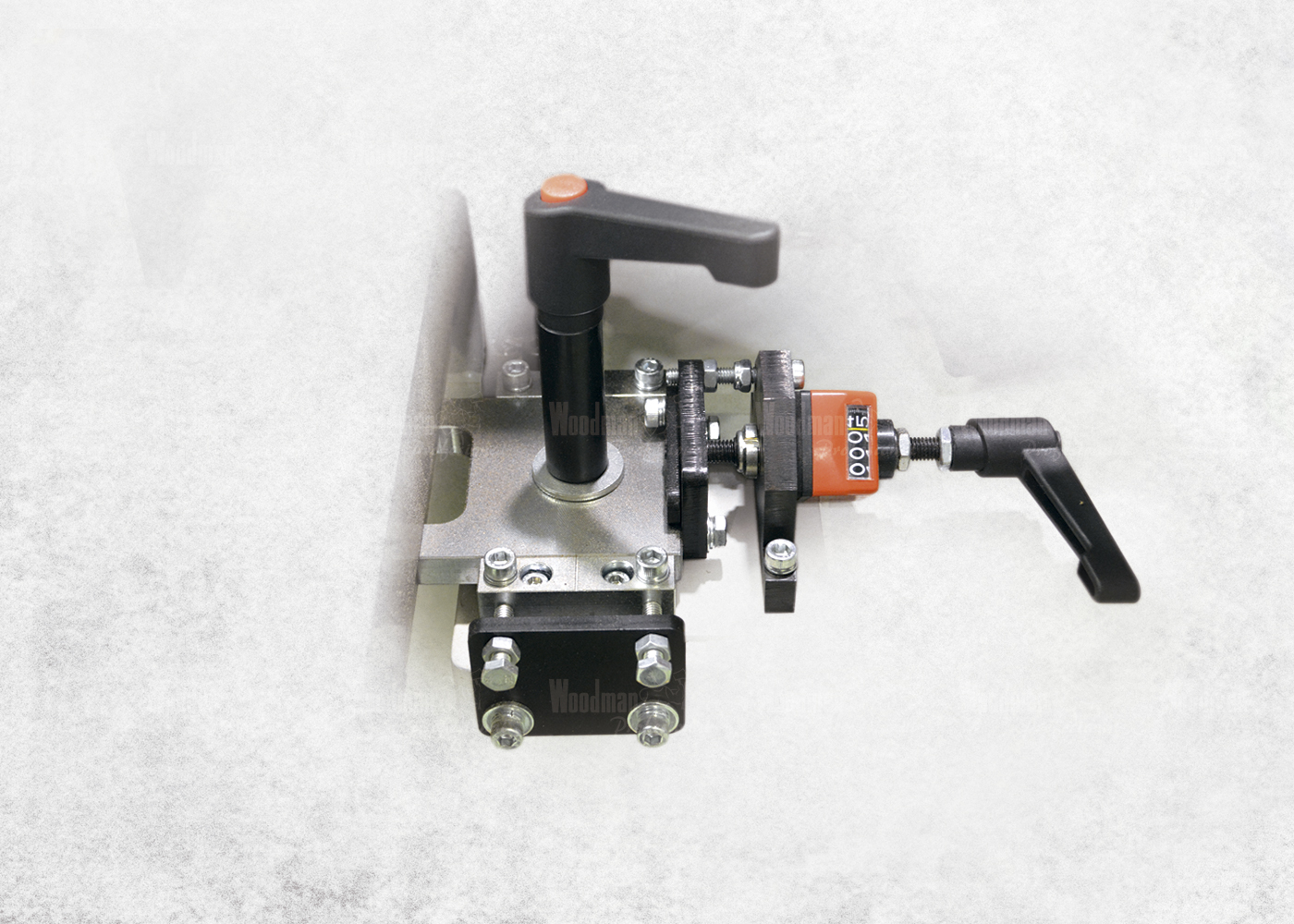

Adjustable in-feed fence for edge width and temperature resistance for better adherence with numerical display.

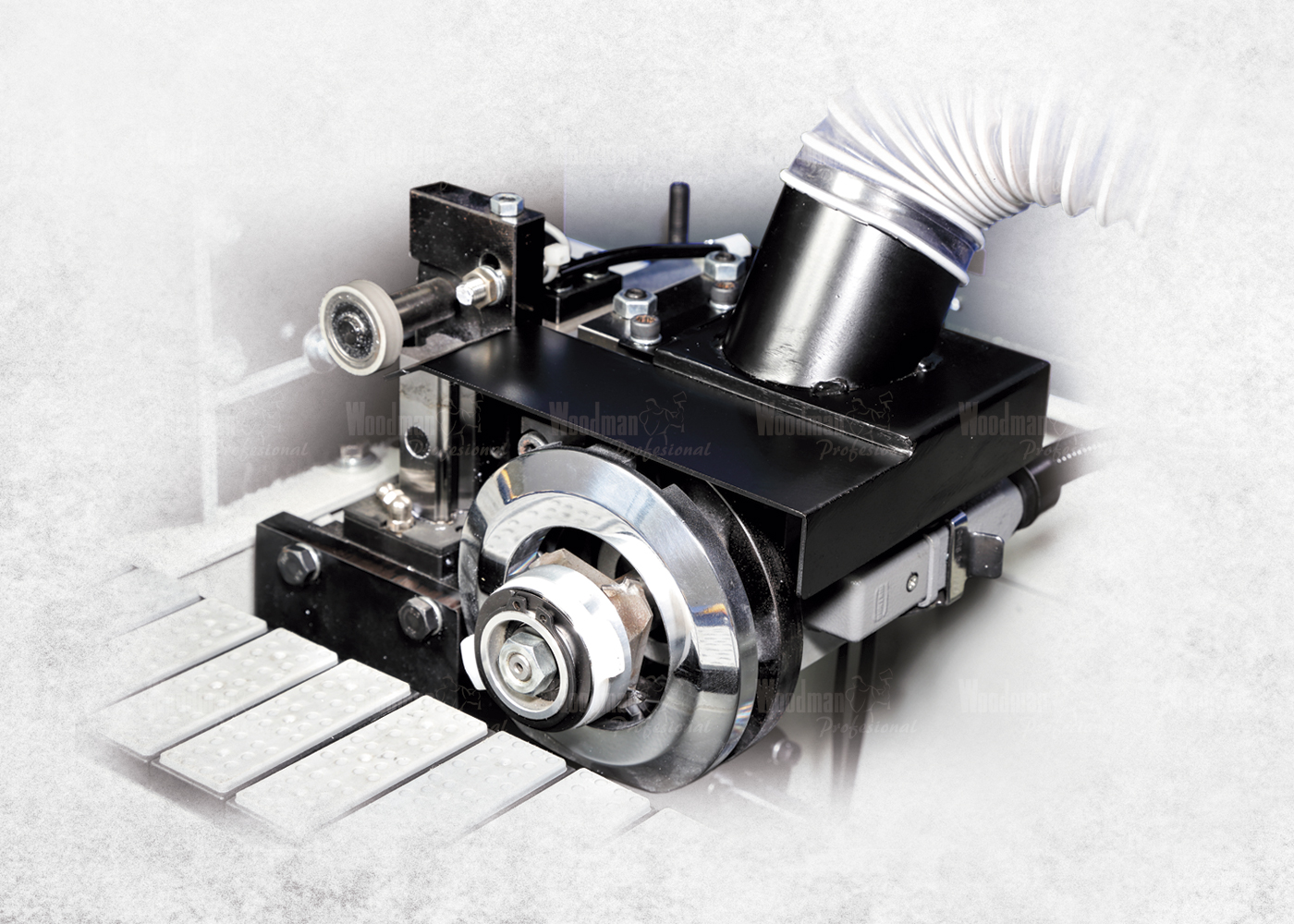

Pre-milling unit (two tools)

Equipped with 2 diamond heads. It allows to go over the edge of the board eliminating possible irregularities before gluing.

Pressure rollers

2 floating pressure rollers for better adherence.

Rounding and end-cutting unit

Designed to perform two functions in the same unit, End cutting and Rounding corner cutting. The PRO3 RCT PLUS model allows to change the function with a simple touch on the touch screen. Precision and fine finish without chips on any type of material up to 3 mm.

Edge trimming unit

Equipped with 12,000 r.p.m. milling cutters, achieving an excellent finish on any type of material. Quick and easy adjustment with a system of numerical displays for measurements.

Radius milling tool

Pneumatic positioning

Bufing unit

It has independent motors and is equipped with 120mm polishing brushes.

Pneumatic surface scraping unit

By means of its timed pneumatic positioning the surface cutter will achieve a perfect finish, eliminating all traces of glue in the joints of the piece.

Total power 5,75 Kw

Max/min edge thickness 0,4 – 3 mm.

Max wood edge thickness 4 mm.

Minimum panel thickness 12 – 45 mm.

Minimum panel width 90 mm.

Minimum panel length 170 mm.

Min. panel length with corner rounding “(12~30) 170 mm.

(30~45) 220 mm.”

Feeding speed 7 m./min.

Feeding speed with corner rounding 7 m./min.

Feeding motor power 0,75 Kw.

Air pressure 7 Bar

Glue tank capacity 1,2 Kg.

Pre milling unit motor power 1,5 Kw. x 1

Tools speed 12.000

Max/min thikness pre milling unit 12 – 32 mm. (45mm. option)

Max. cutting depth 1,5 mm.

Beam elevation manual

End cut unit motor power -

Blades speed -

Edge trimming unit motor power 0,55 Kw. x 1

Edge trimming tools speed 12.000

Rounding unit height 45 mm.

Rounding unit min/max thickness 0,4 – 3 mm.

Rounding unit power 0,35 Kw

Edge trimming tools speed 12.000

Buffing unit motor power 0,12 Kw. x 2

Buffing brushes speed 2.800

Dust chute Ø 3 x 100 mm.

Machine sizes 3.300×1.200×1.200 mm.

Machine weight 528 Kgs.