CHARACTERISTICS

EDGE BANDER

Woodman Profesional has a wide range of professional Edgebanders. The technological and design solutions offered by our models allow us to address the entire professional sector, from the small carpentry workshop, furniture manufacturers, construction, and reform.

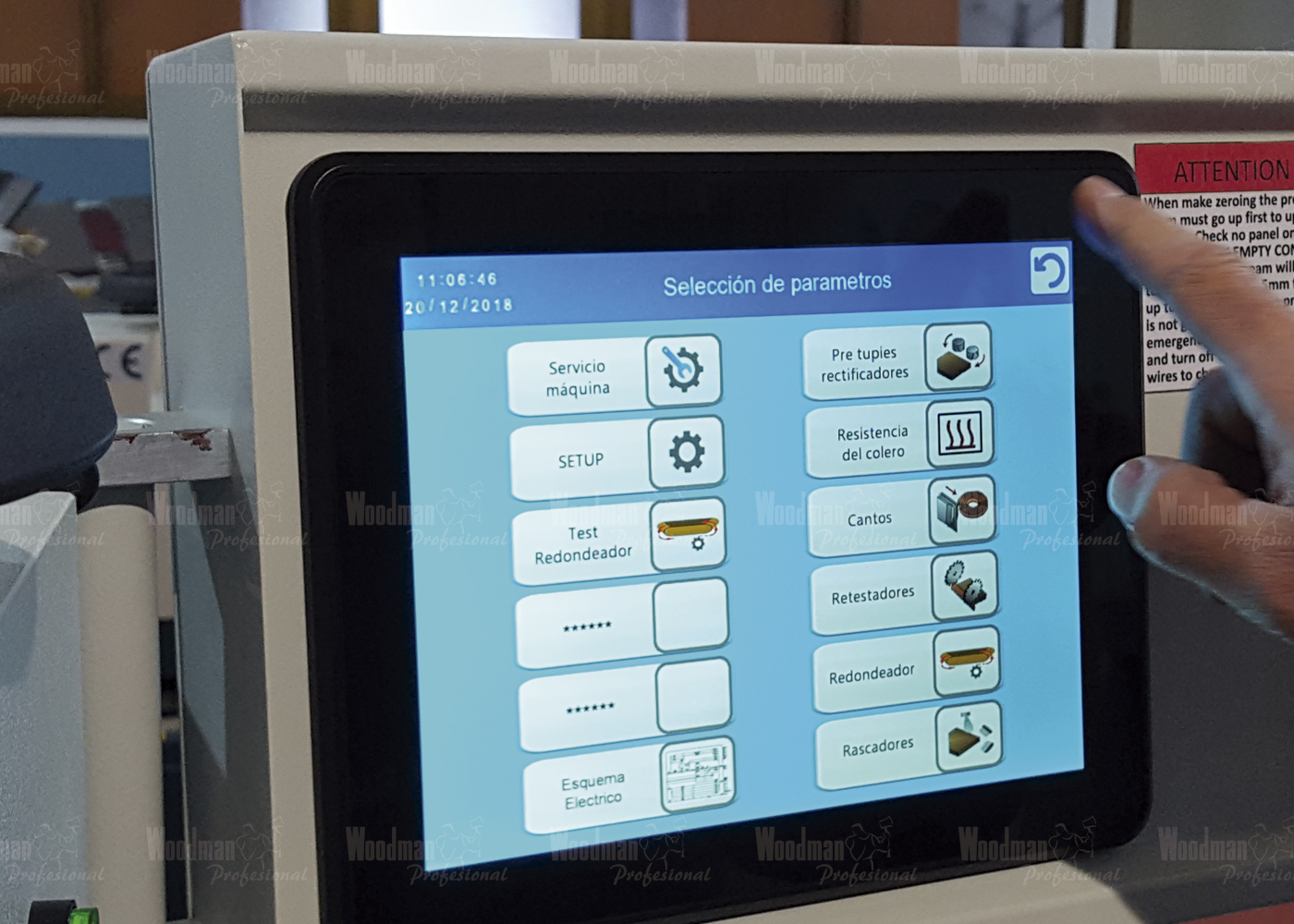

Machines equipped with the best features, the latest technology that provides us with high performance with intuitive and user-friendly handling.

The customization of the models allows us the ideal composition of units for different processes and finishes depending on the material to be worked.

EDGE BANDER PRO6-PLUS

Technological evolution, greater competitiveness, and benefits. Reduces times, complete machining, high precision, and quality finishes on all types of materials.

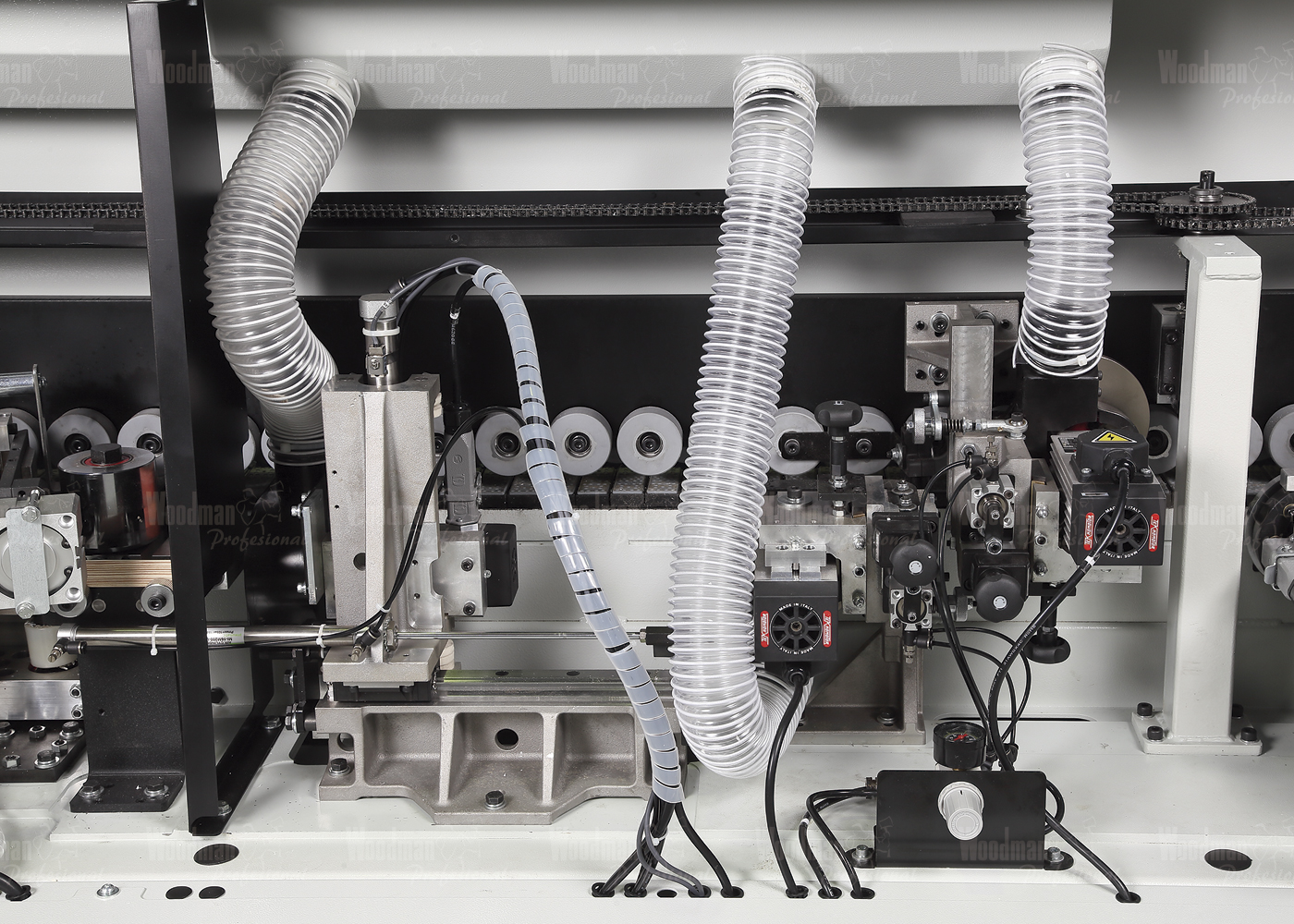

“Pre-milling unit (two tools)

Equipped with independent high frequency motors and diamond heads that provide greater performance in the working process, the calibrated surface allows a perfect finish of the gluing of the edge with the board.

Gluing unit

Gluing unit with glue output regulation and automatic recovery of the excess, with quick system of change of the boiler.

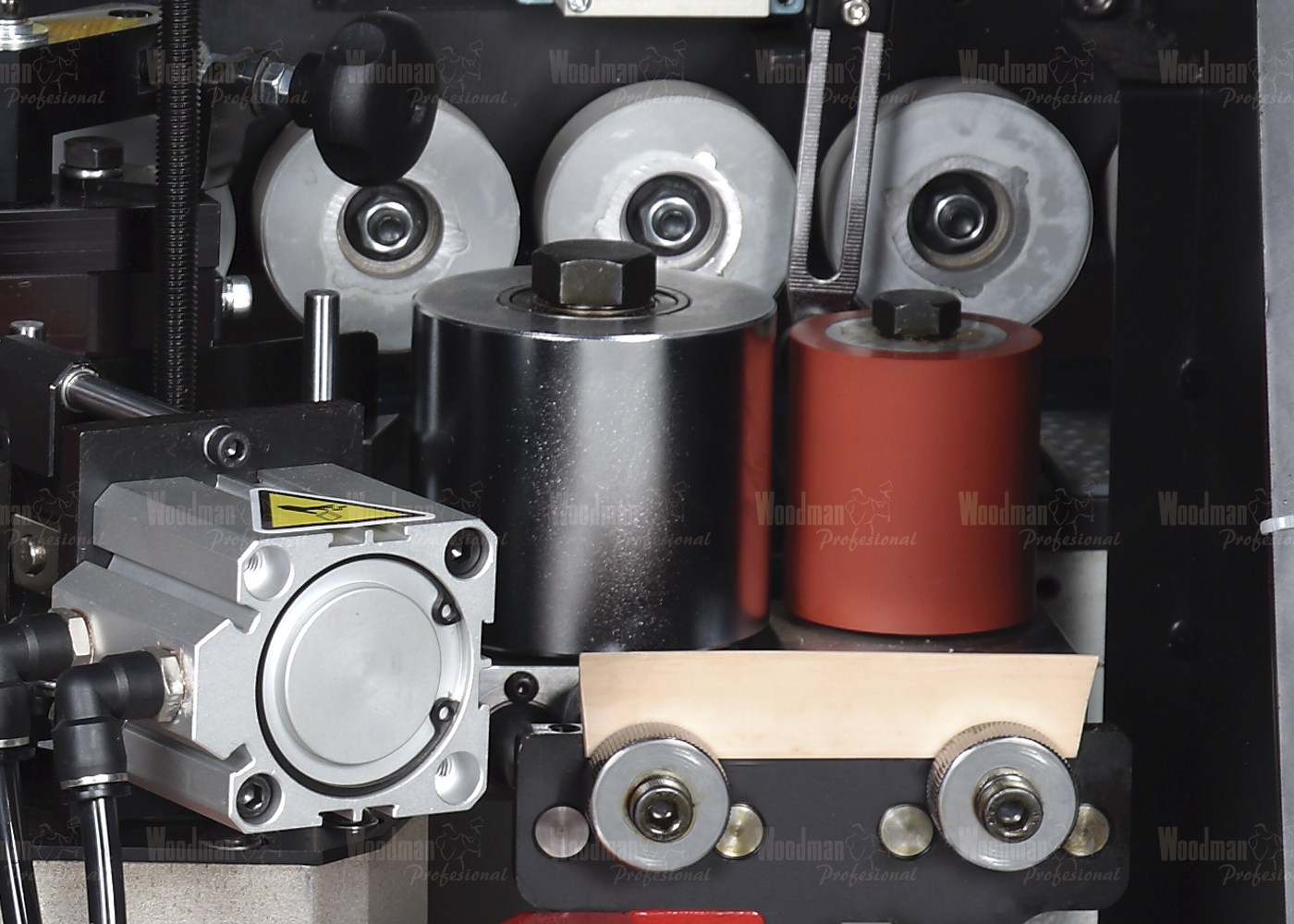

Pressure rollers

2 floating pressure rollers for better adherence.

End cutting unit (double disc)

The unit guarantees perfect cuts of the front and rear surplus thanks to its high-precision linear bearings. The 12,000 r.p.m. speed of the saws allows for a top quality finish.

Edge trimming unit

The quick and easy adjustment with a system of numerical displays for the measurements, together with the speed of 4 upper and lower blades of its cutters allows the group to achieve an excellent finish on any type of material.

Cornering unit

Designed for trimming or rounding off the edges of the pieces. The high frequency motor (0,37Kw) allows the milling cutter to go through the whole piece edging the heads, achieving an optimum finishing of the corners. The unit does not need any adjustment variation when changing the working width or thickness of the workpiece.

Radius scraping unit

Radius scraping unit, upper and lower with air blowers and centralized vacuum.

Pneumatic surface scraper unit

By means of its timed pneumatic positioning the surface cutter will achieve a perfect finish, eliminating all traces of glue in the joints of the piece.

Motorized positioning of the bride.

Bufing unit

It has independent motors and is equipped with 120mm polishing brushes.

Total power 7,4 kw

Max/min edge thickness 0,4 – 3 mm.

Max wood edge thickness 4 mm.

Minimum panel thickness 8 – 60 mm.

Minimum panel width 90 mm.

Minimum panel length 170 mm.

Min. panel length with corner rounding 220 mm.

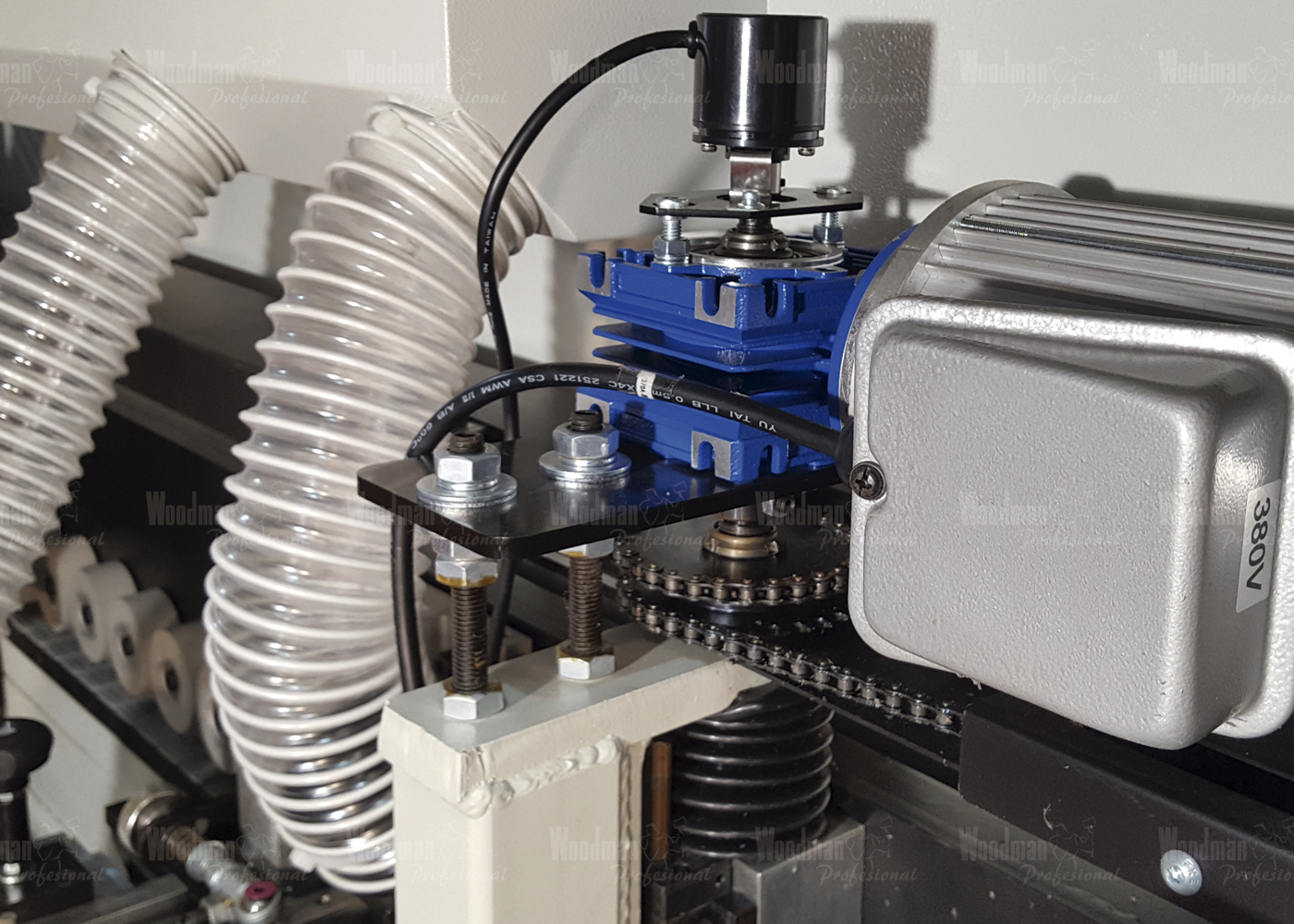

Feeding speed 9 m./min.

Feeding speed with corner rounding 9 m./min.

Feeding motor power 0,75 Kw.

Air pressure 7 Bar

Glue tank capacity 1,2 Kg.

Pre milling unit motor power 1,1 Kw. x 2

Tools speed 12.000

Max/min thikness pre milling unit 8 – 60 mm.

Max. cutting depth 1,5 mm.

Beam elevation motorizada motorized

End cut unit motor power 0,22 Kw.

Blades speed 12.000

Edge trimming unit motor power 0,37 Kw. x 2

Edge trimming tools speed 12.000

Rounding unit height 60 mm.

Rounding unit min/max thickness 0,4 – 3 mm.

Rounding unit power 0,37 Kw.

Edge trimming tools speed 12.000

Buffing unit motor power 0,12 Kw. x 2

Buffing brushes speed 3.000

Dust chute Ø 3 x 120 mm.

Machine sizes 4.150 x 1.050 x 1.480 mm.

Machine weight 920 Kgs.