CHARACTERISTICS

EDGE BANDER

Woodman Profesional has a wide range of professional Edgebanders. The technological and design solutions offered by our models allow us to address the entire professional sector, from the small carpentry workshop, furniture manufacturers, construction, and reform.

Machines equipped with the best features, the latest technology that provides us with high performance with intuitive and user-friendly handling.

The customization of the models allows us the ideal composition of units for different processes and finishes depending on the material to be worked.

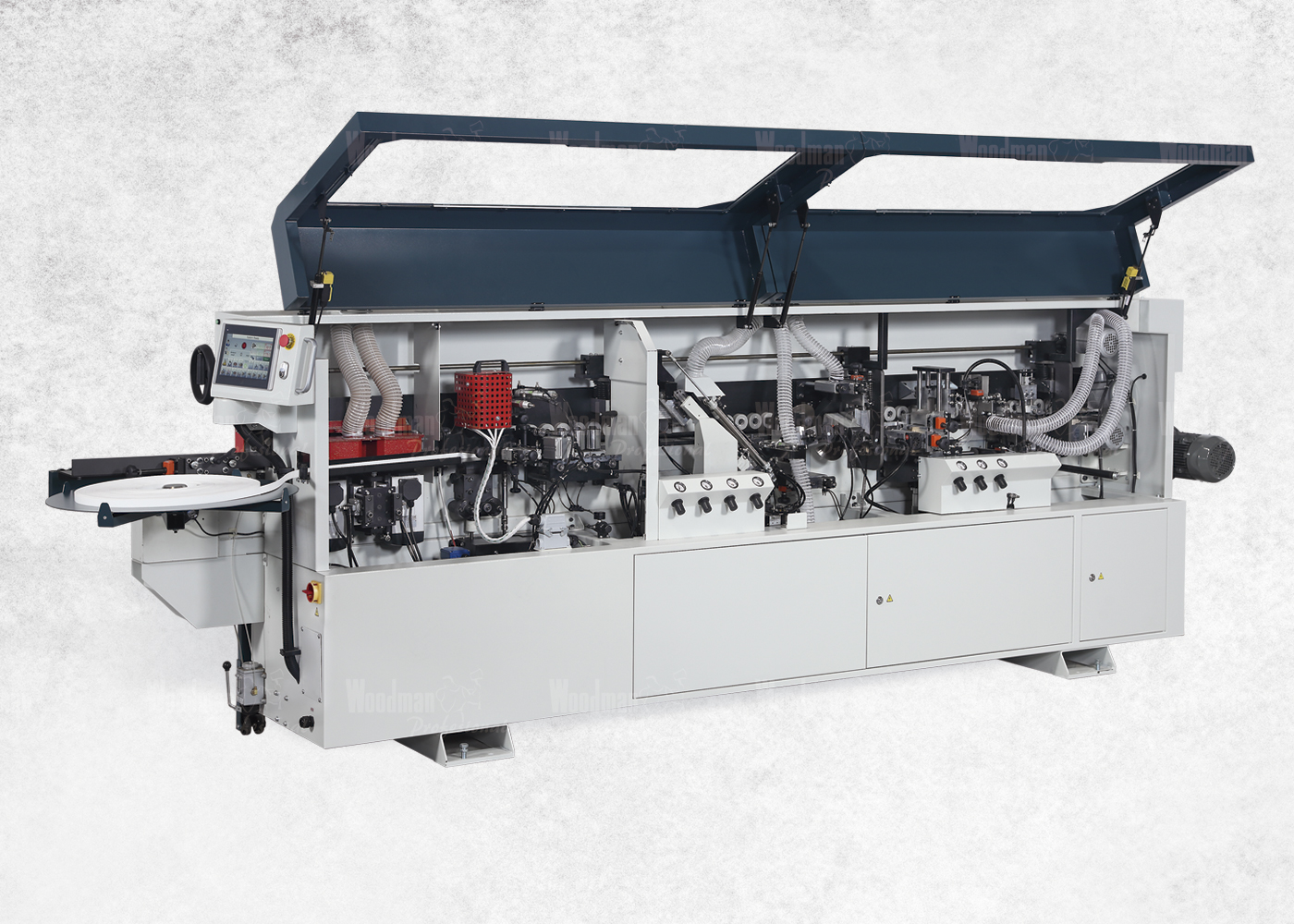

EDGE BANDER PRO7 PLUS

It is the most advanced of the professional series, it combines the greatest technological innovations and all the essential high-end qualities, obtaining a competitive and excellent result in the final production.

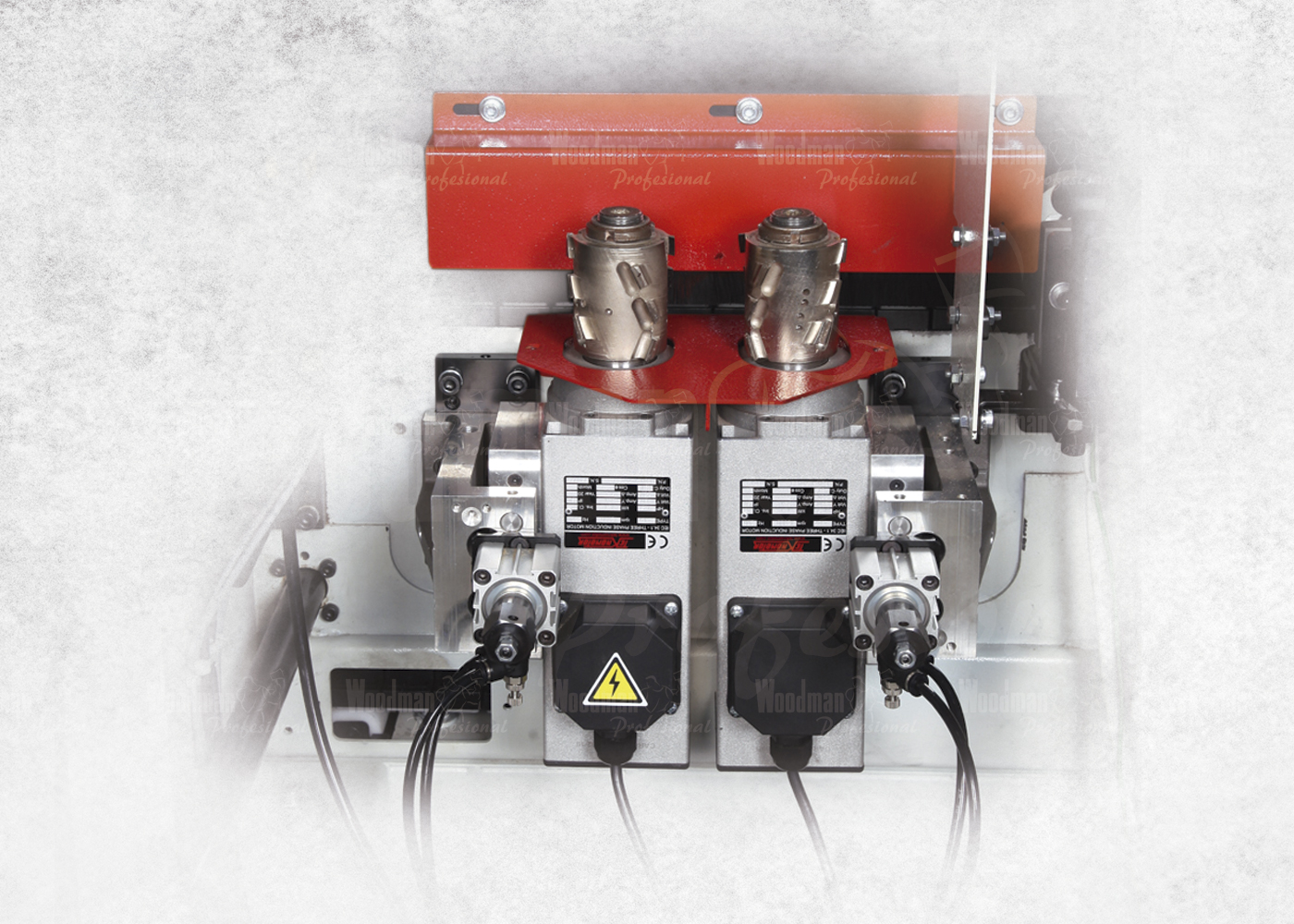

Premilling Unit (Double spindle)

In the PRO 7 model, the Premilling unit stands out, this unit has great power and work capacity. Its greater power is due to the built-in and independent high-frequency motors, with diamond heads, providing more quality and performance in the work process, achieving a perfect gluing of the edge with the board.

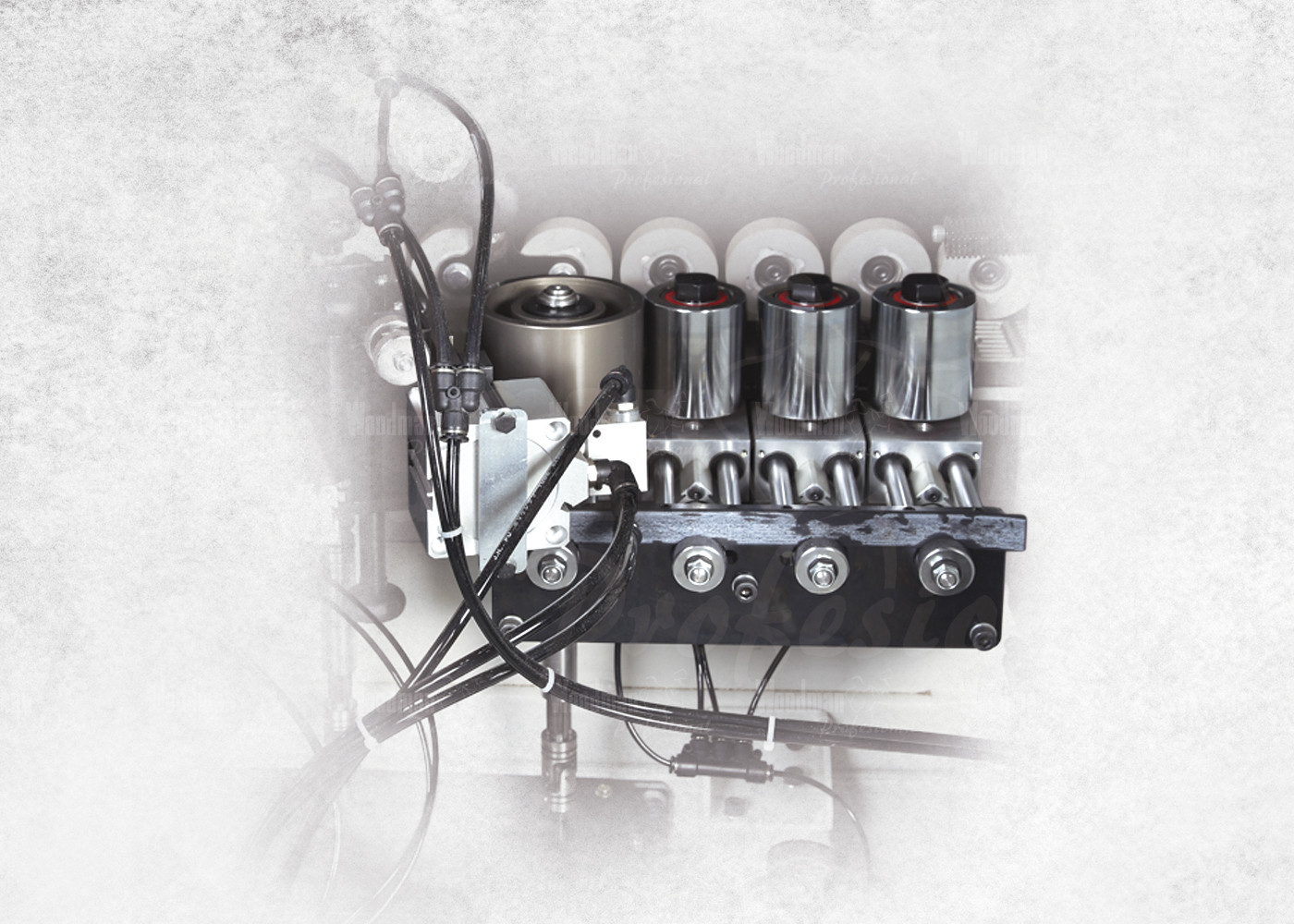

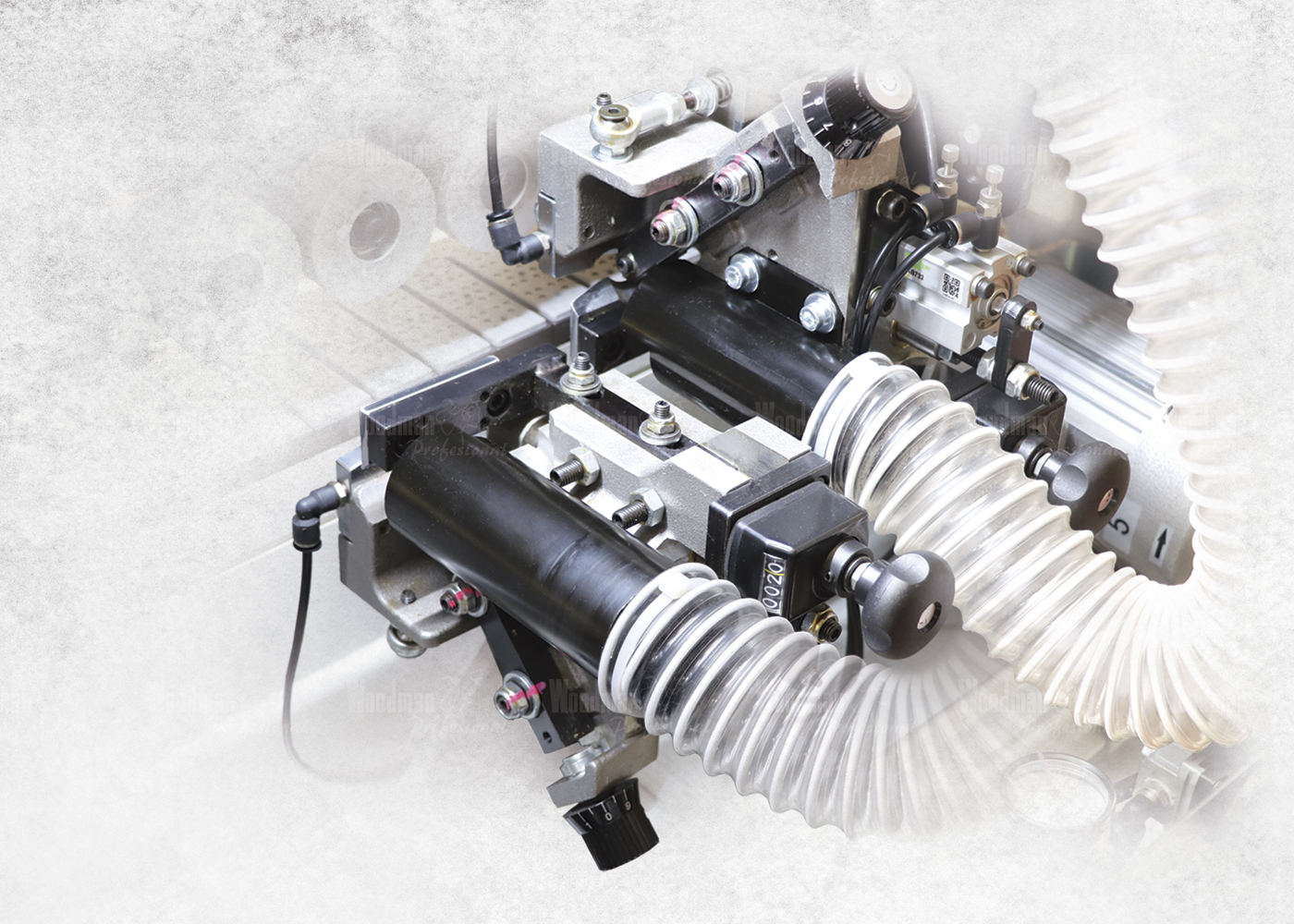

Pressure rollers

4 pneumatic pressure rollers supplied, achieving the same pressure throughout the process. The first roller is Ø100mm motorized, reduces friction and favors a more precise gluing of the edges, avoiding mismatches and achieving a better finish. The 3 Ø60mm rollers are independent and provide more pressure, achieving a better fit of the pieces.

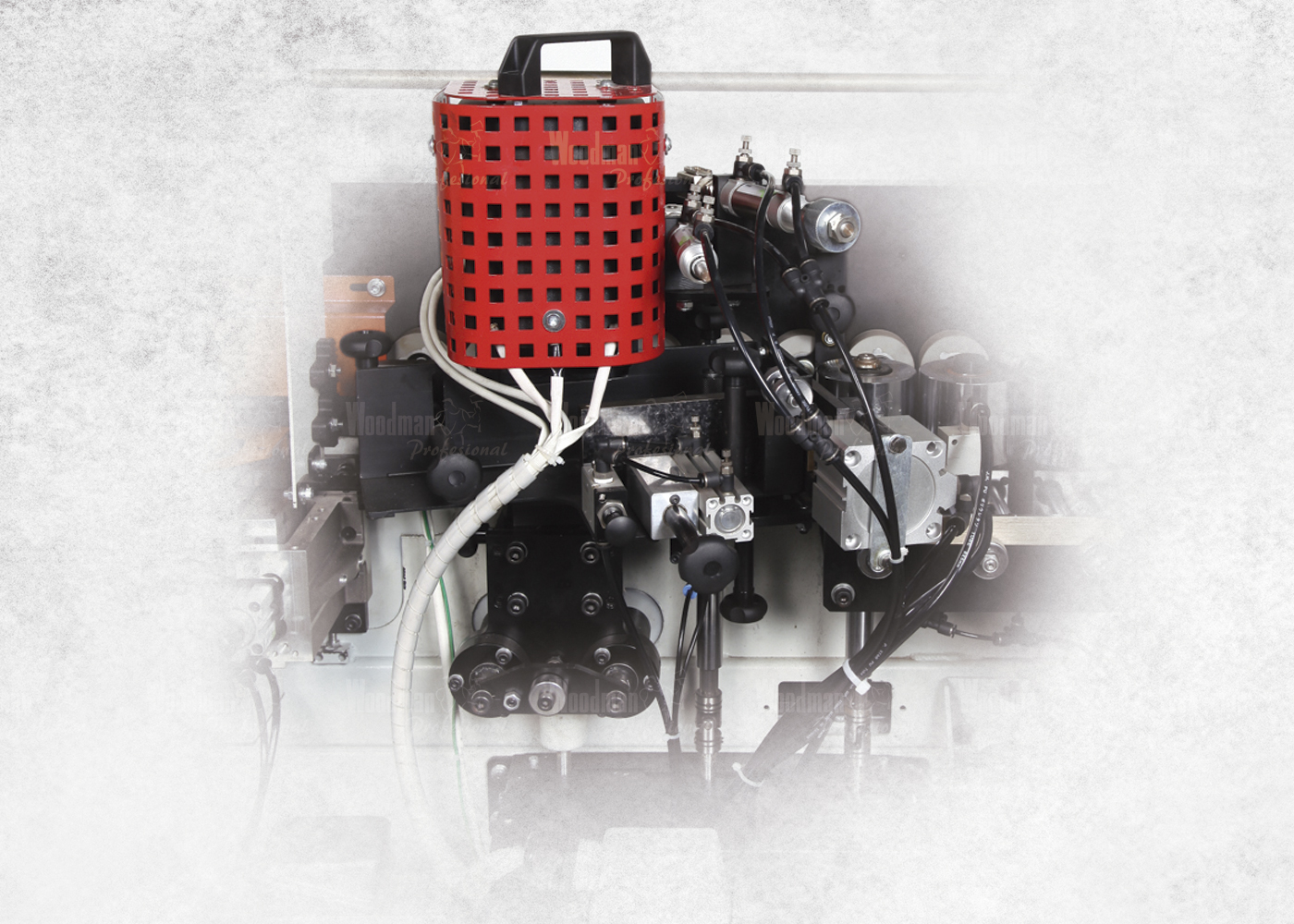

End Trimming unit (Double disc)

Equipped with 2 high-frequency motors and M.D. blades, achieving greater precision in cutting. The unit can change the cutting angle pneumatically from touch screen 15º to 90º. The linear guide system allows us to obtain excellent quality and precision in the front and rear cutting of the piece.

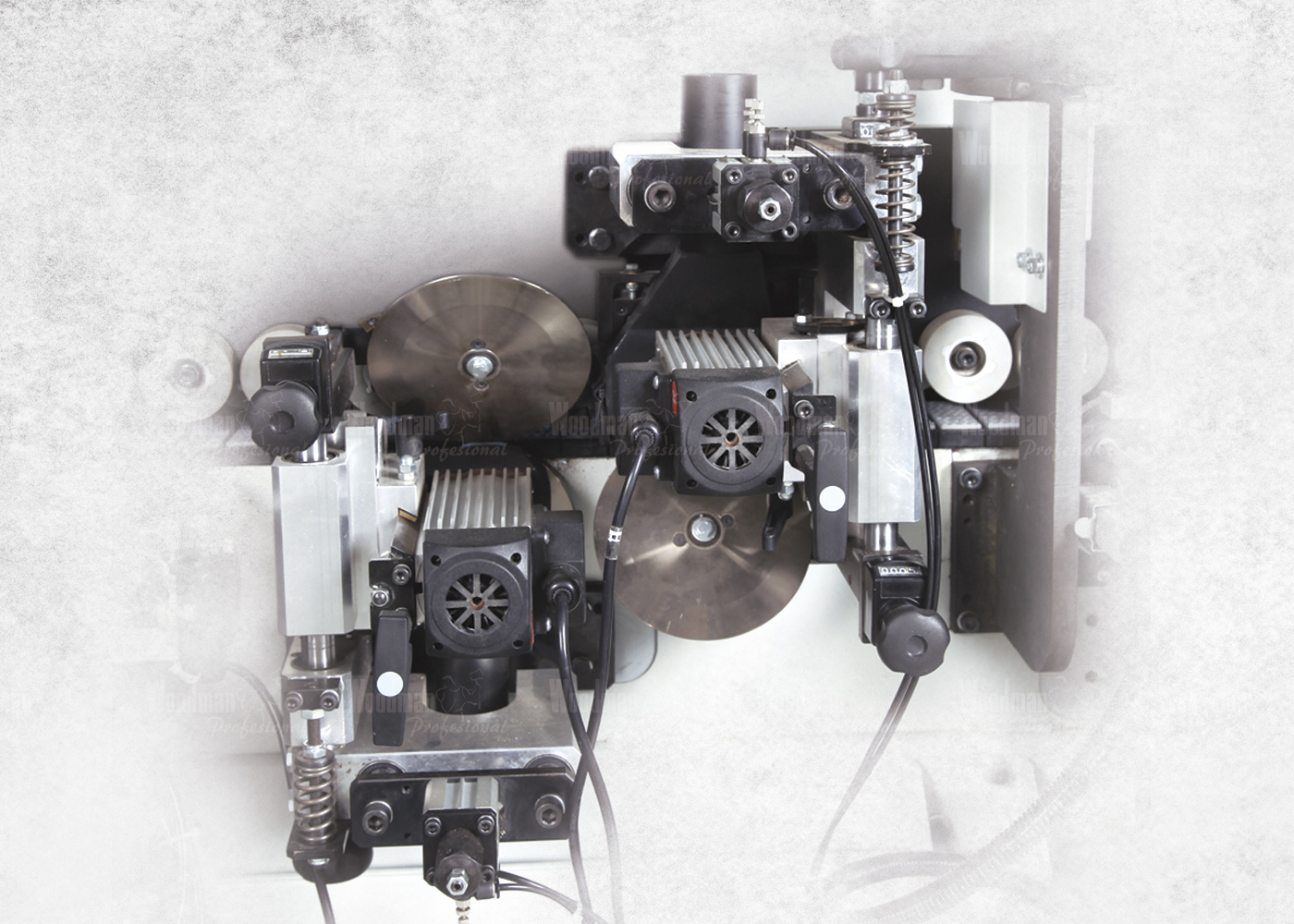

Top&bottom trimming unit

The Triming unit in the PRO 7 has high-frequency motors with higher power for perfect trim on the edge as well as on solid wood. Adjustment is done with digital redaout for quick and easy adjustment.

Positioning of the unit with 3 different cuttings modes: Radius, Flat and Bevel, managing to satisfy the needs of each customer and an excellent finish on any type of material.

Nesting copiers

Nesting copiers technology allows us to advance in the manufacture and obtain an optimal finish in all the pieces with hardware or perforated surfaces with holes.

Control panel

10” touch screen with language selection, total hour counter, total meters and quantity of pieces produced.

Adjustment control by software, list of alarms and faults. Selection of all functions excluding the pneumatic and the auto test of the edge trimming unit.

Radius scraping unit

Radius scraping unit, upper and lower with air blowers and centralized vacuum.

Pneumatic surface scraper unit

By means of its timed pneumatic positioning the surface cutter will achieve a perfect finish, eliminating all traces of glue in the joints of the piece.

Automatic loader for wood ribbons and strips.

Motorized positioning of the bride.

Bufing unit

It has independent motors and is equipped with 120mm polishing brushes.

Total power 11 Kw

Max/min edge thickness 0,4 – 3mm.

Max wood edge thickness 8 mm.

Minimum panel thickness 8 – 60 mm.

Minimum panel width 120 mm.

Minimum panel length “170 mm. (11 M/min.)

250 mm. (16 M/min.)”

Min. panel length with corner rounding “(8~30) 220 mm.

(30~60) 250 mm.”

Feeding speed 11 – 16 m./min.

Feeding speed with corner rounding 11 m./min.

Feeding motor power 2,2 Kw.

Air pressure 7 Bar

Glue tank capacity 1,5 Kg.

Pre milling unit motor power 2,2 Kw x 2

Tools speed 12.000

Max/min thikness pre milling unit 8 – 60 mm.

Max. cutting depth 2,4 mm.

Beam elevation atomático automatic

End cut unit motor power 0,37 kw. x 2

Blades speed 12.000

Edge trimming unit motor power 0,75 Kw. x 2

Edge trimming tools speed 12.000

Rounding unit height 60 mm.

Rounding unit min/max thickness 0,4 – 3 mm.

Rounding unit power 0,37 Kw.

Edge trimming tools speed 12.000

Buffing unit motor power 0,12 Kw. x 2

Buffing brushes speed 3.000

Dust chute Ø 3 x 120 mm.

Machine sizes 4.500 x 1160 x 1500 mm.

Machine weight 1.300 Kgs.